Why Seed Grading is Important

Since humans first developed stable agriculture, seeds have become the world's most essential crop. That's because seed is the bridge between one generation of plant and the next.

There isn't a single good reason for planting poor quality seed, and, thank goodness, this is one thing you can control. The general rule is the larger the seed for any particular variety, the stronger and more vigorous the seedlings are likely to be. Large seeds also produce plants with more tillers than those grown from small seeds.

Make every seed count

As you might expect, a good heavyweight will beat a good lightweight any day. So the aim of seed grading is to maintain this quality from one season to the next by removing all these destructive elements:

- Other crop seeds

- Weed seeds (especially herbicide resistant weeds)

- Straw, soil dust and other inert material

- Immature, shriveled, damaged, cracked, undersized or oversized seed.

The results? You will have selected only the best and highest quality seed for sowing.

The cost of cultivating, fertilizing and controlling weeds in a paddock are high and you cannot afford to permit faulty, foreign or diseased seed to occupy your carefully prepared land.When efficient grading methods are used, the small grain which is unsuitable for seed is taken out and can be sold at market rates, while the screenings make excellent stock food.

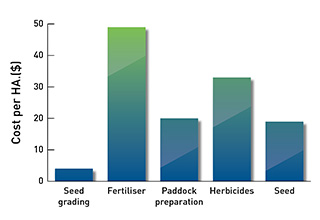

Seed grading has the smallest cost input in crop management but the highest return (see chart).

Both expert official tests and practical results have proved that proper seed grading gives a dramatic increase in yield (up to 45% better from large grain compared to small grain).

Quality grading is economic

Seeds are living organisms and unless looked after will rapidly deteriorate. The value of high seed germination is obvious.

However, the vigour of seedlings is just as important.

Vigour is a seed's ability to germinate, emerge and produce healthy, rapidly growing seedlings even when planted in poor field conditions such as heavy crusting soils or when planted too deep.

A low vigour seed may germinate well in ideal conditions of temperature and soil moisture. However, in less than perfect conditions it's another story. Poor emergence may limit yield. Vigour is one of the most important characteristics of seed quality because of its vital effect on seedling establishment.

This was clearly shown by trial work conducted by the Department of Agriculture in Western Australia.

Seed quality improves emergence

Major findings were that small cereal seed will germinate just as well as large, plump seed, but emergence is considerably less for pinched, small and broken grain:

| Seed type | Germination (%) | Emergence (%) |

|---|---|---|

| Large | 95 | 85 |

| Pinched | 99 | 73 |

| Small | 91 | 72 |

| Broken | 21 | 3 |

Seed with less than 80% emergence is not considered satisfactory and will require higher sowing rates to obtain optimum plant density. Grading your seed maximises germination and emergence. In other words, grading produces high seed vigour.

Seed grading improves the competitive nature of seed

Larger seed not only has greater vigour but emerges faster. The speed of germination and emergence is a powerful factor because it occurs early in the growth of the crop. Early emerging seedlings have a high probability of being larger at stem elongation and of producing more grains than those that emerge a few days later.

Seed grading will actively encourage consistency as well as competitiveness of seed. Uniformity of seed permits more even distribution of grain through the drill. Seed spacing is important as blanks and then clusters are a disadvantage for optimum plant density.

Alf Hannaford, the father of the seed grading industry in Australia, once compared the importance of competitive seed to the composition of a football team:

"A football team with weak men loses the game. Twelve good men and six weak ones cannot make a good performance. The weak impairs the strong and are unable to withstand the opposition".

The importance of seed coleoptile

The coleoptile is the sheath (or shield) which guides the shoot through the soil to the surface. The first leaf emerges from the coleoptile. It functions chiefly as a protective tube for the young foliage, which grows up through it to the surface. A high percentage of abnormal seedlings have a split in the coleoptile which restricts emergence. This is illustrated in the table below, which shows the effect of coleoptile quality on seed emergence.

Immature seeds with split coleoptiles are often the grains from the top and bottom of the smallest heads produced from late tillers.

These often appear when heavy rain falls late in the crop development . Abnormal seedlings and dead seeds occur at a higher rate in small seed. Removal of this unproductive seed is ample justification for grading.

| Treatment | Field emergence of seed (%) |

|---|---|

| Wet soils: Slightly split coleoptiles Intact coleoptiles |

5 92 |

| Intermediate moistures: Slightly split coleoptiles Intact coleoptiles |

11 97 |

| Dry soils: Slightly split coleoptiles Intact coleoptile |

2 97 |

Legume seed - grading even more critical

Grading is critical with legume seed. That's because grain legumes have a very poor capacity to compensate for low plant numbers. So yield is vitally dependent on seed quality. Even the most experienced farmer cannot accurately assess the true quality of legume seed by visual inspection alone. Weather damage, rough handling, insects, poor storage, disease – all these vital factors may not be immediately obvious. Good crops are not grown on hope alone. You invest too much in a crop to risk poor establishment. Sowing correctly graded legume seed plays an essential part in overcoming all these problems. Only correctly graded seed ensures vigorous, healthy legumes.

Herbicide resistant weeds - yet another reason to grade

Herbicide resistance is increasing. This is arguably the gravest challenge to agriculture this decade. Weeds that have developed resistance to herbicides include annual ryegrass, wild turnip, wild oats, bindweed, capeweed, barley grass and Indian hedge mustard.

GRDC estimates are that resistance to herbicides could cost up to $100 per hectare in grain legumes and $30 per hectare in wheat in the first year alone. Nobody can afford an infestation of herbicide resistant weeds. Many paddocks have high levels of resistance in their weeds due to the sowing of contaminated seeds. Grading helps reduce weed seed reserves and contain the spread of herbicide resistant weeds. Seed grading has many advantages:

- Saves time and money

- Maintains profitable control of weeds

- Delays herbicide resistance

- Avoids annoying blockages at sowing time.

One of the central aims of a herbicide resistance management program is to reduce the number of viable weed seeds. Sowing seed which has been thoroughly cleaned is an integral part of herbicide resistance management.

Prepare your seed for a golden harvest

Your local Hannaford seed management specialist prepares high quality seed for sowing. Every grain fed into a Hannaford machine is separately handled with precision, and here's the sequence that achieves this:

- Threshing - deawning to remove awns, whiteheads and tails.

- Pre-cleaning - removes lighter impurities.

- Length separation - removal of straw, long and short material.

- Width separation - good definitive separation through screening and scalping.

- Accurate seed treatment (pickling) using unique Hannaford Flow-Through Technology.

Why treat seed

Seed treatments are an extremely cost-effective mechanism for disease control. Traditionally, seed was only treated to control smut diseases in cereals. However, the technology has since been advanced to include early protection against foliar and root diseases in all types of crop plants. Insect pest control and yield enhancement, the latter through stimulation of plant enzyme systems and improved accessibility of trace elements, have also been achieved.

Seed treatment is for:

Disease control

- Diseased grain produces diseased plants.

- Failure to control disease leads to yield loss.

- Diseased grain incurs dockage or rejection at receival points.

- Foliar disease control can help to ensure that a high yield of premium grade grain is produced.

Insect control

- Treatment of seed with an insecticide before storage protects the seed from injury or consumption by insect pests of stored grain (eg weevils and grain borers).

- Treatment of seed to protect germinating and emerging seedlings from insects such as red legged earth mite and wire worm.

Yield improvement

- An improvement in yield can be accomplished by the control of plant diseases, and by using seed treatment chemicals that stimulate or aid in plant growth and development.

- Vitaflo® Seed Treatment can help to increase grain yield by controlling smuts and bunts, and by stimulating enzymes involved in the nitrogen cycle within the plant. Plant responses to seed treatments vary, according to environmental factors and disease pressures.

- Application of trace elements such as Zincflo® Plus to the seed ensures that nutrients are available to the seed during the critical period of plant establishment. The early alleviation of nutrient deficiency enhances crop yield and quality.

Diseases controlled by seed treatments

Many cereal diseases can be controlled using seed treatments. The presence of these diseases, whether affecting the roots, foliage or head, can have an adverse effect on crop yield and grain quality, and hence reduce profit. Correct seed selection and fungicide treatment is essential for achieving maximum crop potential. Hannaford mobile equipment is designed not only to clean seed but select the plumpest seed for sowing.

Hannaford seed management professionals have expert knowledge in seed processing combined with experience in local conditions.

Key benefits of seed treatment application by a Hannaford specialist

Specially designed and manufactured by Hannaford, the flowable fungicide treater delivers the correct volume of seed treatment to a measured quantity of seed giving unique accuracy and maximum product performance, along with:

- Adhesion to the seed by correct use of purpose developed equipment.

- Thorough distribution on all seed - more even coverage.

- At the grading stage, rubbish is removed, so no seed treatment is wasted.

- Peace of mind because you are ready to sow at any time with trouble free quality seed.

- Hannaford seed treatment formulation - Hannaford brands are developed by the company for best quality seed coverage giving growers maximum product advantage and no wastage.

Using Hannaford is the most cost effective form of seed protection.